TOOLBOX

Ruskin

Starting about 10 years ago, anti-microbial coating provider Bio Shield Tech LLC began its foray into the ventilation industry. While the company first sold its coatings to ambulances for door handles and other high traffic equipment, the EPA-registered technology works just as well at fighting pathogens and mold in ductwork.

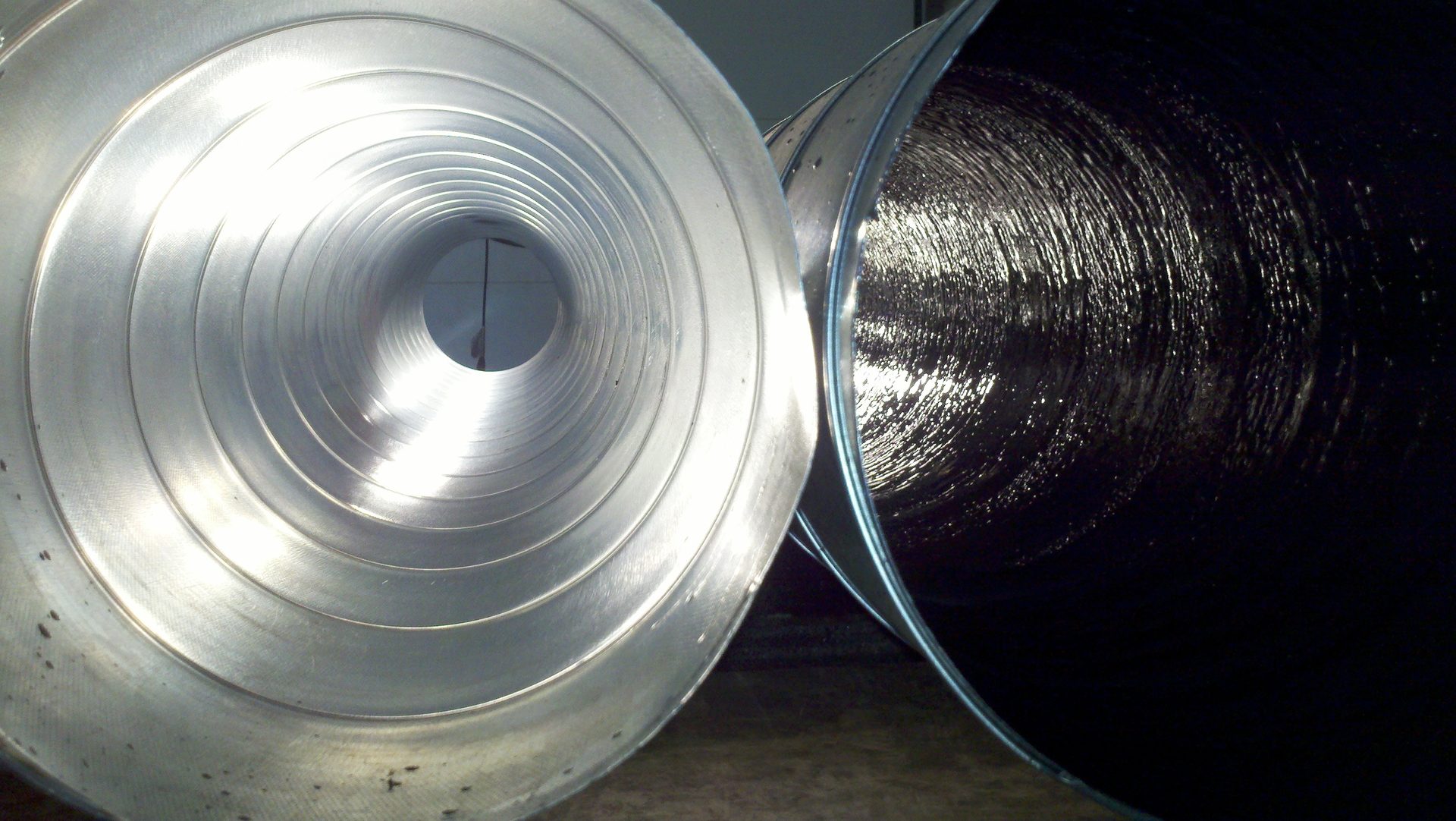

Bio Shield’s principal competitor in the HVAC sector is pre-coated steel that comes with an antimicrobial coating directly from the manufacturer. AK Steel owns the exclusive license for applying an antimicrobial coating of silver ions to coiled steel, working with specific service centers to distribute to sheet metal shops across the country.

Shops pay a premium to meet air handling standards for hospitals, research labs and even schools, but Bio Shield offers an alternative in allowing shops to apply an approved, two-coat antimicrobial silver ion epoxy themselves – with digital training from professionals who’ve done it a hundred times. While the shop does have to expend labor, coating in the shop helps lean manufacturers maintain a modest inventory of coils and a steady cash flow purchasing gallons of a product that ships on a just-in-time basis anywhere in the U.S.

Silver Ions Protect Ductwork from Microbial Growth Decades after Application

By Austin Keating

Silver Bullet AM by Bio Shield uses zeolite “sacrificial” silver ions that maintain an equilibrium across the bottom of a 1mm matte of epoxy, applied either in the field or in the shop. Ions pull themselves toward microbial growth on the surface, mitigate it and then go dormant; those ions that don’t expend themselves then spread out, becoming less concentrated but just as effective for years, and even decades, in systems that meet benchmarks like consistently staying below the dew point.

Silver, like the base metal copper, is naturally antimicrobial, but being a precious metal, it has other properties that lend itself to aerosolization and a long shelf life. With the Silver Bullet system, it’s applied at a greater concentration than factory-applied silver coatings. Because of this, sheet metal shops serving high-profile projects ranging from Denver International Airport to Facebook data centers have turned to Silver Bullet.

“The selling point behind applying antimicrobial coatings yourself is that there’s more available silver, which means it will last longer – fighting mold, mildew, bacteria and harmful pathogens on the coating surface that recur over and over again in the air stream,” concludes Jeff Drucker, CEO and founder of Bio Shield Tech LLC.