TOOLBOX

Turning Up the Heat

Pumps, exchangers and upgraded equipment.

W-Series Air Conditioning & Heat Pump Equipment by Nortek Global HVAC

The introduction of Nortek Global HVAC’s W-Series air conditioning and heat pump equipment, for residential and light commercial applications, completes the final phase of an overall redesign of Gibson, NuTone and Frigidaire branded 1.5 to 5-ton, single-phase air conditioning units and heat pumps.

The W-Series’ air conditioning (WSA) is available in 13, 14 and 16-SEER models and the heat pump (WSH) in 14 and 16-SEER models. Standard features include Copeland scroll compressors and a liquid line filter-drier for field installation in an accessible position to facilitate easy periodic change-outs. Featured aesthetic and functional additions include a coil-protecting wire guard that adds cabinet structural integrity and holds a plastic mesh in place to safeguard against hail and accidental contact damage. The wire guard is secured by the top and three corner screws to promote quiet operation and easy disassembly for coil cleaning access. The W-Series’ anti-corrosive polymer drain pan also includes more drainage holes to eliminate potential standing water.

In keeping with past product enhancements launched in early 2019, the W-Series will include charging chart access for an easy and accurate refrigerant charge. Nortek’s proprietary charge assist tool, www.chargecalculator.com, can be accessed conventionally, or by scanning a weather-proof quick response (QR) code called “Charge Me” affixed on the unit’s exterior cabinet above the refrigerant access port. The tool helps account for sub-cooling, fixed orifices, thermostatic expansion valves (TXV), ambient temperature at time of charging, lineset length and other variables. nortekhvac.com.

Photo provided by Nortek Global HVAC

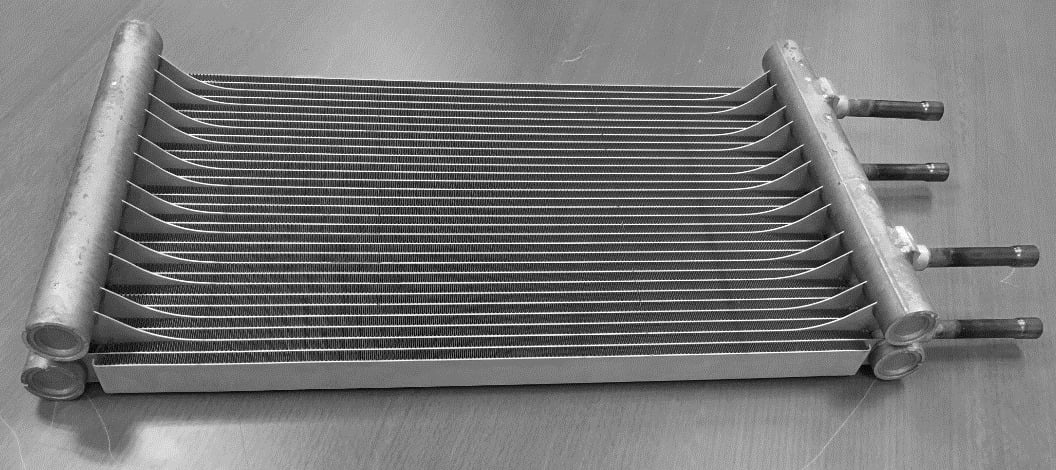

Interlaced Micro Channel Heat Exchangers By Danfoss

Danfoss won three 2020 AHR Expo Innovation Awards, one for its Interlaced Micro Channel Heat Exchanger, or iMCHE. The iMCHE integrates multiple circuits into a single coil with shared air heat transfer area, controlling each one independently by a multi-circuit system. The compact, all-aluminum iMCHE uses whole air side heat transfer area when operating under partial load conditions to improve system efficiency by more than 20 percent. It also offers 30 percent higher heat transfer efficiency, and lower refrigerant charge.

Through its innovative tube bending structure and passage setup, as well as multi-row compact structure and high-tolerance distributor solution, iMCHE enables design flexibility, modularity, customizability, and extensive flow arrangements that allow chiller and rooftop manufacturers to meet unique challenges. While public concern for climate change continues to increase and higher energy standards are predicted, the iMCHE allows equipment to easily meet new standards with low cost impact.

“Danfoss is committed to bringing innovation and next generation solutions to the market to help our customers and industry improve energy efficiency, reduce emissions and meet climate regulations,” said John Galyen, President, Danfoss North America, in a statement. “Winning three awards this year is a testament to our investments and we look forward to working with our industry partners to deploy these solutions in the HVACR market.” danfoss.com.

Photo provided by Danfoss

Pump-Assisted Split Loop Energy Recovery Heat Exchanger by Advanced Cooling Technologies

The Advanced Cooling Technologies, Inc (ACT) Pump-Assisted Split Loop Energy Recovery Heat Exchanger (Pump-Assisted AAHX) has won the 2021 AHR Innovation Green Building Award for its achievements in bringing unmatched energy efficiency and design flexibility to commercial air handling units.

Pump-Assisted AAHX is capable of achieving the highest level of energy recovery and cost savings available year-round for split air streams. This is particularly valuable for buildings requiring a large amount of outside air to maintain optimum IAQ standards – which is especially attractive in today’s COVID-19 climate.

The Pump-Assisted AAHX combines traditional air-to-air heat pipe technology and a pumped two-phase system to take advantage of both passive (no energy input) and active (some energy input) operational modes and provide energy recovery year-round. This allows AHUs to be sized smaller, positioned more optimally, and consume less energy.

“As the demand for energy efficient buildings continues to soar, the need for high levels of energy recovery becomes a vital component of HVAC system design,” said Scott Garner, vice president of industrial products at Advanced Cooling Technologies, Inc. “Building designers are often faced with significant space and layout constraints that make incorporating energy recovery hardware a challenge. The compact footprint, installation flexibility, and minimal energy consumption of our Pump-Assisted Split Loop Energy Recovery Heat Exchanger allows designers to create layouts that are better for building air distribution and return – without sacrificing energy efficiency.” 1-act.com.