TOOLBOX

AHR Expo HVAC Machinery and Tool Guide

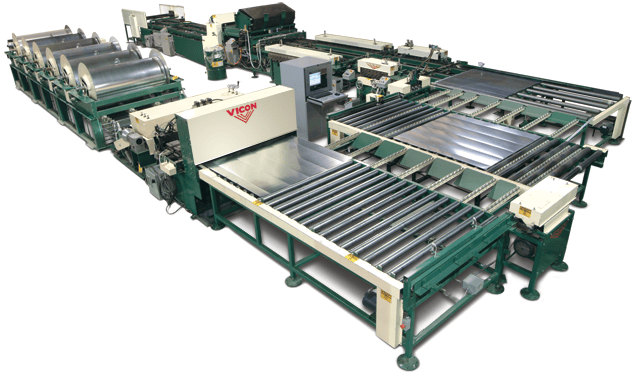

Full Coil Line - Vicon | Booth C3938

Vicon’s Coil Line fully automates duct fabrication with six parts:

- Automatic rectangular duct blanking system Duct-line Express: Includes a patented uncoiler, feeder, straightener unit, beader, nothing unit and heavy-duty shear.

- Lockseam System, model V-510-LS: The Lockseam system accepts beaded, notched and sheared blanks and automatically forms the Pittsburgh or snaplock seams.

- Dual Head Cleat Edge Former, model V-CEF-DH-5: Rollforms a 7/16” cleat edge on both ends of the duct.

- Dual Head TDX Rollformer, model V-TDX-DH-5: Produces SMACNA’s T25a or T25b connections. Material forms to produce SMACNA-approved transverse flange connection.

- Automatic Duct Liner Application System, model V-510-DD: Uncoils duct liner, applies liner adhesive to the sheet metal and automatically pins the liner to the sheet metal. This machine can work with various types of liner, including Armaflex and K-Flex insulation.

- Full Wrap Automatic Brake System, model V-516B-FW: It’s a heavy duty hydraulic bending unit. Your duct is completely formed and ready to be seamed once the duct is automatically ejected by the computer-controlled gripper unit.

TurboShear Drill Attachment - Malco Products | Booth C2740

Insert this attachment into the chuck of a drill to make straight, curved or square cuts in most common sheet metals. A sleek, lightweight aluminum cast shear head and molded drill clamp allow maximum portability. The compact telescoping drill clamp adjusts to fit both length and width of popular drill sizes, including smaller bodied impact drivers.

The shear's wide-opening jaws can operate at high or low speeds for the control you need to follow a precise trim line, navigate crosscuts through profiles of metal building and roofing panels or cut through layered metal and seams, even the ribs of spiral duct.

Fabricating Coil Line - Mestek Machinery | Booth C1330

The Iowa Precision Pro Fabriduct HVAC Duct Fabricating Coil Line has been enhanced to produce full width longitudinal seams. These can create less chance of leakage in duct systems. Features include, but aren’t limited to:

- The fastest feed rate in the industry.

- E-Z load coil drum assemblies for quick spool changeover (no lifting devises to add to your lift truck).

- Soft-start motors for long life.

- Direct hydraulically driven decoilers system on every coil station with hydraulic hold-downs and low-friction pockets.

- Grid Skate Roll System for every coil station.

- Coil Select for feeding material into the coil processor.

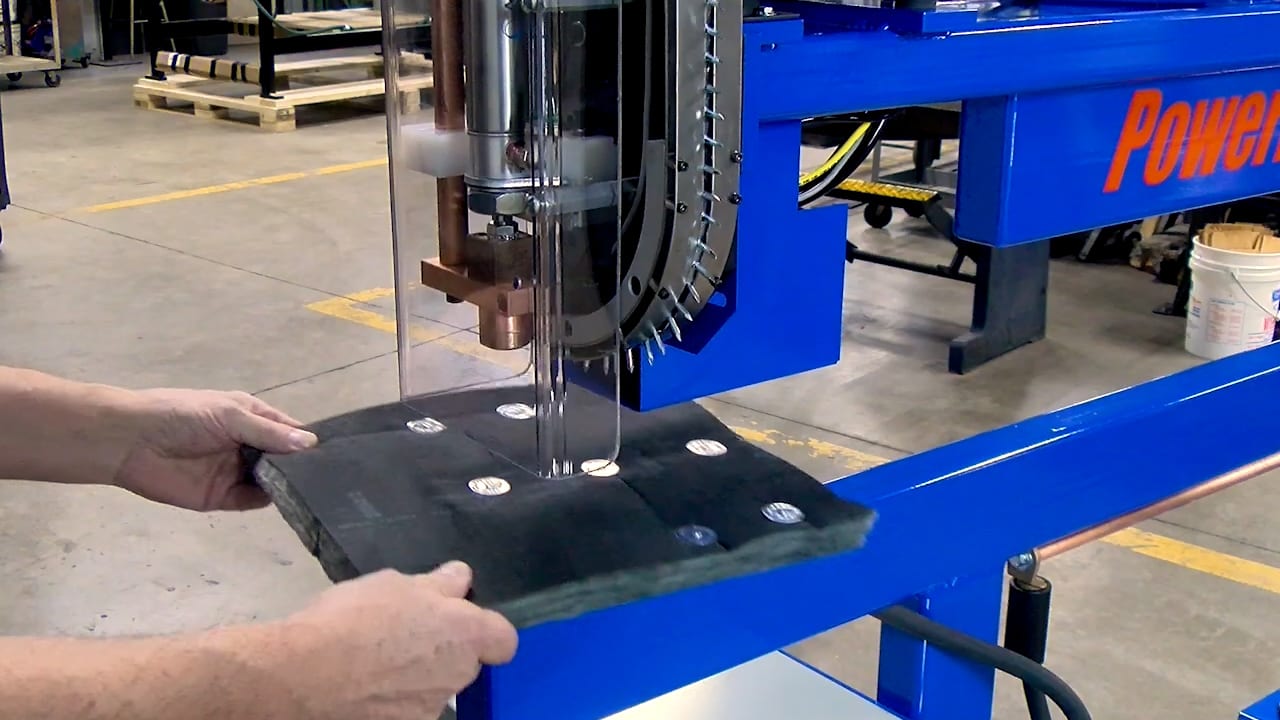

PowerPinner 7005HS - Gripnail, part of Carlisle | Booth N7341

With a high-output transformer and an automated feeder, the PowerPinner 7005HS by Carlisle brand Gripnail can do 83 pins per minute. It produces a strong weld for 1/2" all the way to full 2" pins, fastened to 16-26 gauge sheet metal. Simply set the machine for the gauge you want based on pin size and thickness of sheet metal. Weld and dwell time are calculated by the PLC. Depressing the ergonomic foot pedal while the Continuous Fire switch is on allows the operator to continuously weld pins without having to lift their foot off the pedal.

Round Duct Connector - Ductmate Industries, part of DMI Companies | Booth C2120

The Spiralmate round duct connector was developed to provide a simple method of connecting sections of spiral round ductwork at a lower overall cost.

- Standard sizes from 8” – 72” in 2” increments (consult factory for additional sizes).

- Available in specialty metals.

- Spiralmate has been tested to 18” w.g. positive pressure and 10” w.g. negative pressure.

- Spiralmate is not recommended for applications with duct gauges heavier than 16 GA or lighter than 28 GA. Both profiles will accept 12 GA longitudinal duct seam.