BACKSTORY

Overhead ductwork is a convenient, aesthetic and effective method of HVAC air distribution, however its efficiency varies greatly as per heating and cooling seasons.

Science 101 class teaches the convection principles that warm air rises and cool air descends. That’s the challenge overhead ductwork has to overcome to accommodate efficiency in both winter and summer periods and the variable seasons in between.

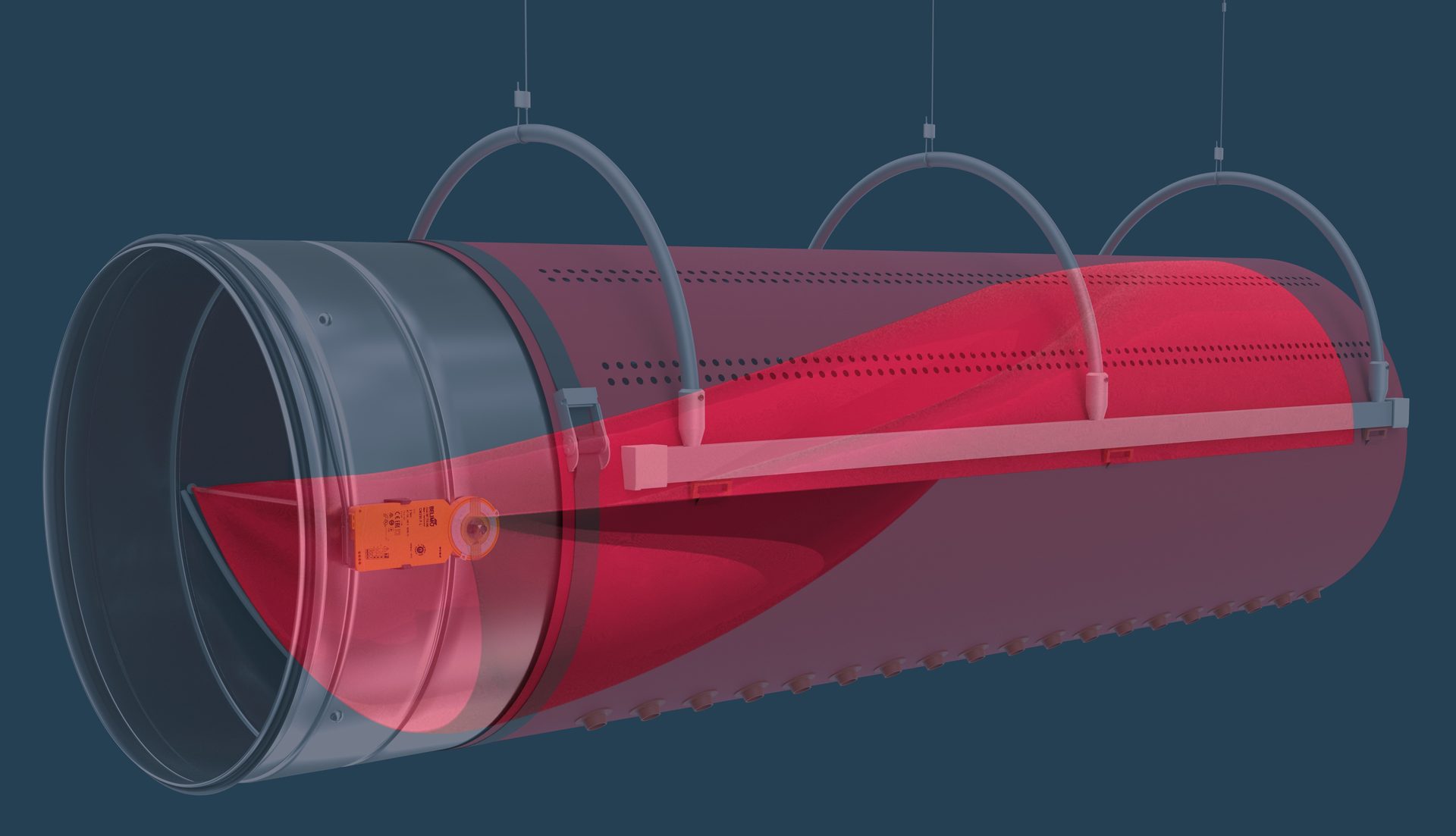

The fabric duct industry believes it has a solution. Several manufacturers have developed duct products that project air upward for cooling and downward for heating. These products handle two different flow models, air volume requirements and air pressures within the same duct. The innovation that allows this is an internal damper-like mechanism with an attached piece of fabric the length of the duct. Depending on cooling or heating, the damper moves up or down to position the attached fabric at the top or bottom. Moving the damper upward for heating season, for example, also positions the fabric connection upward, thus allowing the supply air to push the entire length against the top of the duct. This blocks any orifices from emitting airflow through the upper hemisphere. Instead, the supply air is allowed to flow through the duct bottom hemisphere’s orifices. It’s pushed more toward the occupied zone six feet above the floor, depending on what custom orifice array the engineer or design/build contractor specifies. The opposite occurs in cooling mode.

The upper hemisphere orifices are micro perforations for high air changes at a lower velocity. Conversely, the lower hemisphere air distribution can use jets, nozzles or larger orifices to accelerate the heated air downward or laterally, which are particularly effective for uniform air dispersion strategies with high ceiling systems.

This damper/fabric process can also be applied to horizontal elbows, reducers and concentric transitions.

A combination heating and cooling duct is ideal for open office areas, classrooms, production facilities with high temperatures from operating machinery, and large occupied spaces where precision temperature comfort is critical. High ceiling spaces also receive more uniform heating benefits from the strategy. It’s particularly beneficial during seasonal transitional periods with large outdoor temperature swings throughout the day. Spaces in these conditions typically require heating in cool mornings and evenings, but air conditioning during the day. These are typical scenarios for the northeast, southeast and Midwest during the Fall and Spring.

These ducts’ cooling and heating transitions are activated by an optional thermostat or a third party actuator that reports to a building management system (BMS) via a network. A manual crank comes standard and is useful for redundancy at properties with potential power outages.

Aside from this new innovation, there are several reasons fabric duct has been proven to be more energy efficient than metal duct in studies. Studies prove fabric duct uses less energy than metal, because its air dispersion methodology distributes the air more uniformly throughout a space with fewer dead or static air spots. One study, “Thermal Comparison Between Ceiling Diffusers and Fabric Ductwork Diffusers for Green Buildings” compared the heating performance of metal versus fabric duct at various flow rates. Conducted by the Department of Mechanical Engineering at Iowa State University, Ames, Iowa, the study proved fabric duct heats rooms faster, more uniformly, and as a result more efficiently. The fabric system was proven 24.5-percent more efficient than the ceiling metal diffuser system. The metal diffuser system fell short, because a significant fraction of distributed air stayed along the ceiling. The fabric system’s higher velocities and multiple outlets resulted in more energy absorbed by the room. Set points are reached faster resulting in decreased mechanical system runtimes.

Combination heating/cooling fabric ducts carry a slightly extra cost versus traditional fabric duct, but there is a return on investment (ROI) payback when considering energy savings. Given the current high cost of steel, combination ducts are competitive with metal duct. The air comfort difference is priceless.

Billy Farr is the inside sales and support manager at FabricAir, Suwanee, Ga. Farr has nine years of experience at FabricAir and has helped HVAC contractors and engineers design more than 100,000 commercial fabric duct air distribution systems. FabricAir manufactures the VarioDuct, which is a combination heating/cooling duct that can be seen at https://www.youtube.com/watch?v=dwJH3q44HHA. Farr can be reached at bif@fabricair.com or 502-493-2210 ext. 201.

How Ductwork can be Equally Efficient in Heating and Cooling Modes